Newly alloy matrix

The alloy composition and microstructure optimized by thermodynamic and dynamic theory models can improve the resistance of the insert against high temperature wear and plastic deformation.

With alloy grain adjustment technology, the cubic phase grains are finer and more evenly distributed, which improves the high temperature performance of the insert, while the strength of the edge line is optimized by the adhesion and the gradient coupling change of solid solution.

Hydrogen Gradient Transition Layer Technology

The hydrogen gradient transition layer adopts PCN technology, with fine and dense grains coating, which further improves the high temperature performance and oxidation resistance of the insert.

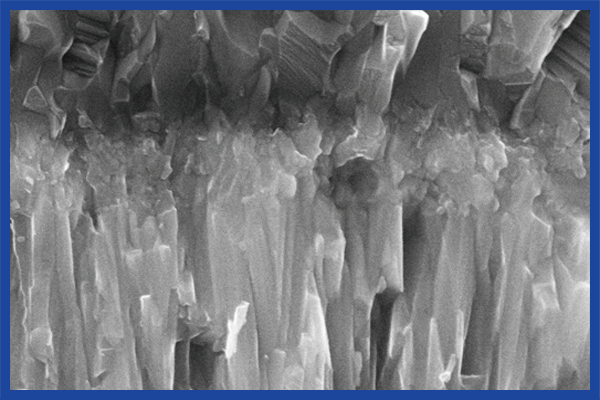

Ultra-Thick Coating Technology with Fine-grained Columnar Structure Al2O3

It has outstanding high temperature performance and wear resistance, and with the two-color marking layer and the super smooth Al2O3 coating of the rake it improved the smoothness and uniformity of the edge line and the quality of the surface.

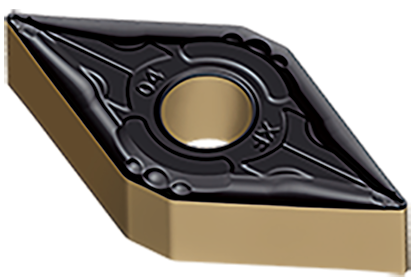

-XF Finishing Geometry

Curved angle of inclination insert can ensure the strength of the insert and reduce the cutting resistance.

The full-curved structure of the insert improves the versatility.

The special chip breaker design upgrades the chip control performance in the finishing machining.

-XM Semi-Finishing Geometry

Special cutting edge structure with both sharpness and strength.

Newly designed chip breaker geometry.

With excellent coating grades, it has high chip strengthand excellent wear resistance, achieving efficient and stable machining.

The new YBC103 coating grade greatly improves the high temperature oxidation resistance, wear resistance and plastic deformation resistance of the insert.

It can realize stable machining on high-speed cutting and improve the efficiency.

ZCC CT will continue to innovate, and provide customers with comprehensive solutions for modern machining.