Engine is the heart of automobile, cylinder block is the key parts of engine, the manufacturing precision, including dimension precision, geometric tolerance, surface quality are critical to the performance of engine. For milling of cylinder block, we adopt CNC high-speed machining center to substitute traditional production line. This places more and more strict requirements on dedicated use of cutting tools. ZCCCT offers entire solutions for cylinder block.

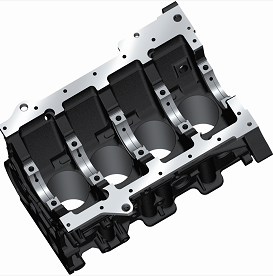

Top surface, bottom surface and side surface machining

FMD 02 series face milling cutter, pentagon insert with 10 cutting edges; open geometry, large rake angel design and soft cutting action, good surface quality, it is the first choice for cast iron components machining.

Back side milling

FMP 02 series face milling cutter, screw clamping system, easy insert indexing, large chip evacuation space, smooth chip removal; can apply in various kinds of machining, including surface, step surface with right-angle, slots and grooves, etc.

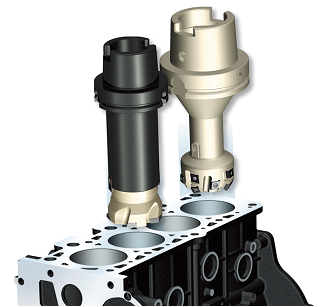

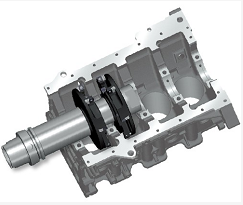

Cylinder hole-making

Rough boring tools for cylinder holes

Finish boring tools for cylinder holes

Cylinder holes rough boring special tool, with horizontally installed insert, large depth of cutting, large chips evacuation space facilitate smooth chip removal with high efficiency.

Special tool for cylinder holes finish-boring, with vertically mounted and properly distributed inserts, high precision of machining, one operation can finish both back chipping and chamfering.

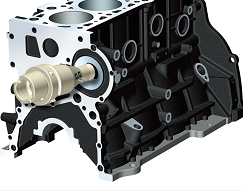

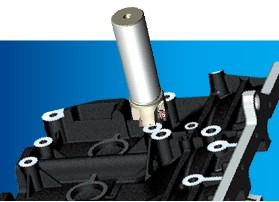

Hole-making of water pump

Special tool for water pump hole-boring,shaping process and hole-boring can be machined in only one pass, improve production efficiency.

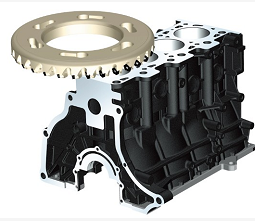

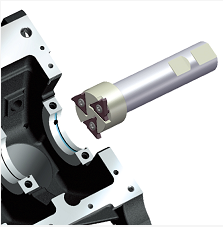

Semicircle hole-making of crankshaft

Special tool for semicircle hole-making of crankshaft, optimized tool design can minimize vibration and ensure machining precision and quality, two passes for five location machining.

Oil groove machining

SMP 05 series Face and side milling tool,with three vertically mounted cutting edges, high mounting and machining precision, can make to non-standard tool,five machining locations can be operated in synchronous processing.

Inter surface hole-making

1588 SL series deep hole twist drills, with double guiding edge-line, more reliable and stable, l/d ratio of 12, 20 and 30 for selection, can well meet the demands of deep-hole drilling with collision.

Thrust surface machining

Only one type of insert can apply in both left and right side cutter body, convenient for management with lower cost;simultaneously machining left and right side cutter body with high efficiency,and can turn into the special tool for 5 parts machining.

Boss machining

EMP 11 multi-function boss milling tool, with screw clamping, easy insert indexing, large chip evacuation space, can machine surface, step face with right angle, slots and grooves, etc.

Plug-hole machining

Screw clamping, easy for tool adjusting and insert indexing, stepped boring can be done in one operation.

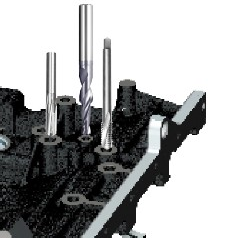

Drilling, Reaming and screwing

Multiple different types of solid carbide drills, reamers, taps, thread milling cutters and other products with high-precision, can meet different requirements of hole-making.