Water pump is a machine for conveying liquid or increasing press, it transports the mechanical energy or energy from external sources to liquid, also increase liquid energy. It plays a major role in conveying liquids includes water, oil,acid-base liquid, emulsion and liquid metal and so forth, also can convey mixture of liquid, gas and suspended solids.

It demonstrates outstanding performance by adopting advanced ultra-fine grain with nano-coating techniques in CVD coating grade in combination with high toughness substrate. It also exerts outstanding machinability even under difficult condition,like large cutting depth, high feed rate, high speed cutting in stainless steel, cast steel, and other materials machining.

◆Coating features

---Ultra-fine Al2O3 Coating, outstanding wear resistance

performance

---Special coating technique ensures closer bonding between coating and substrate

---Polished surface on coating is more suitable for sticky materials machining

Substrate

---Gradient cemented carbide, higher toughness

1. Rotor Block (material: cast steel)

Position of machining: Internal hole and face

Diameter of work piece:Φ

Insert: YBM253/SNMG190612-ER

Cutting data: n=10 r/min, f=

2. Bearing body (material: 1Cr18Ni9)

Position of machining: face andinternal hole

Diameter of workpiece: Φ1480

Insert: YBM253/SNMM250924-ER

Cutting data: n=10 r/min, f=0.28 mm/r, ap=5 mm

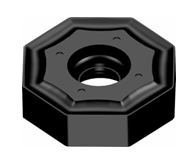

3. Casing (Material: Casting steel)

Position of machining: Interface Milling

Tool: FMA07-200-C60-ON08-12

Insert: YBM253/ONHU08T508-PM

Cutting data: n=600r/min, f=

4. Impellor( material: 1Cr18Ni9)

Position of machining: face and internal hole

Insert: YBM253/CNMG160608-EM

Cutting date: n=40 r/min, f=

5. Blade (material: 1Cr18Ni9)

Position of machining: blade surface

Tool: FMR02-080-B27-RC16-05

Insert: YBM253/RCKT1606MO-ER

Cutting data: n=400 r/min, f=

For more productive, innovation-oriented and highly effective cutting products and solutions, Please contact one of our engineers and check our ZCCCT products catalogs.