The chassis of blowers casing is for Tri-lobe Roots Blowers, which is mentioned in the cases below. Its most important feature is the little change of low volume while the pressure is adjusted in a permitted range during the application process. In addition, there is a wide selection of operating point for pressure. What's more, it has no process of internal compression and the transmission of air is mandatory. Also, oil is not contained in the transmitting agents. The consistency of dynamic balance for rotor is high, and the overall vibration is low. Therefore, it operated with safety and reliability in a long term. Also, it is very convenient to maintain due to its compact structure. It possesses more advanced structure and higher machining efficiency with improved design. The function of Blower is to transmit the clean air, and it transmits the semi-water gas, water gas, sulfur dioxide, and other neutral gas under purification process as well. However,inflammable, explosive, toxic and highly corrosive agents are not permitted to transmit. It is widely applicable in economic sectors covering metallurgy,light industry, textile, coal, mechanical industry, electric power industry,petroleum, cement industry, chemical engineering industry, construction materials, environmental protection, paper making, sewage disposal, aquaculture industry, and pneumatic conveying.

Crafts:

◆Rough Milling for Equipping Face of Chassis Pedestal and Flange Face of inlet Hole

◆Finish Milling for Equipping Face of Chassis Pedestal and Flange Face of inlet Hole

◆Rough Milling for Rake Face and Flank Face of Rotor cavity

◆Finish Milling for Rake Face and Flank Face of Rotor cavity

◆Rough Milling for Flange Face of vent Hole

◆Finish Milling for Flange Face of vent Hole

◆Rough Boring of Rotor Cavity Hole

◆Finish Boring of Rotor Cavity Hole

◆Thread Hole Drilling for Rake Face and Flank Face of Rotor Cavity

◆Locating Hole Drilling for Rake Face and Flank Face of Rotor Cavity

◆Bolt Hole Drilling on Pedestal

◆Thread Hole Drilling for Flange Face of Vent Hole and Inlet Hole

◆Hole Chamfering for Thread Holes and Bolt Holes on Each Faces

◆Thread Hole-making for Rake Face and Flank Face of Rotor Cavity

◆Thread Hole Tapping for Flange Face of vent hole and inlet hole

Rough Milling for Equipping Face of Chassis Pedestal and Flange Face of inlet Hole

Rough Milling for Rake Face and Flank Face of Rotor Cavity

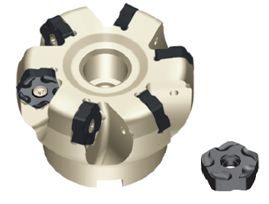

FMD02 Series of Face Milling Tools

Rough Milling for Flange Face of vent Hole

FMD 02Series of Face Milling Tools

Tool: FMD02-100-B32-PN11-10

Insert: YBD252/PNEG110512R-CR

Cutting data: V=

Finish Milling for Equipping Face of Chassis Pedestal and Flange Face of inlet Hole

Finish Milling for Rake Face and Flank Face of Rotor Cavity

FMP02 Series of Face Milling Tools

Finish Milling for Flange Face of vent Hole -

FMP02 Series of Face Milling Tools

Tool: FMP02-100-B32-SE09-08

Insert: YBG202/SEET09T308PER-PF

Cutting data: V=

Rough Boring of Rotor Cavity Hole

Tool: FMP02-100-B32-SE09-08

Insert: YBG202/SEET09T308PER-PF

Cutting data: V=

Finish Boring of Rotor Cavity Hole----large diameter boring cutter

Tool: LD60-D380-400455

LR170-CN12(seat)

Insert: YBD152/CCMG120408-PM

Cutting data: V=

Tool: LD60-D380-400455-40L(cutter head)

F114-67153-CC06(Chuck)

FB90-LD-65*75(Seat)

LCW94-65*72(Balancing Weight)

Tool: YNG151C/CCGT060204-SF

Cutting data: V=180m/min f=0.05mm/z ap=0.3mm

Thread Hole Drilling For Rake Face and Flank Face of Rotor Cavity

Tool: 1576PC05-1750

Cutting data: n=1800r/min f=

Locating Hole Drilling for Rake Face and Flank Face of Rotor Cavity

Tool: 1576PC05-1750

Cutting data: n=1600r/min f=

Bolt Hole Drilling on Pedestal

Tool: ZTD02-280-XP32-SP09-02

Insert: YBG205/SPGT090408-PM(External edge)

YBG212/SPGT090408-PM(Internal edge)

Tool: 1576PC05-1400

Cutting data: n=2100r/min f=

Hole Chamfering for ThreadHoles and Bolt Holes on Each Faces

Tool: 1143SC90-2000

Cutting data: n=1600r/min f=

Thread Hole-making for Rake Face and Flank Face of Rotor Cavity

Tool: 4111-M20*2.5

Cutting data: V=

Thread Hole Tapping for Flange Face of vent hole and inlet hole

Tool: 4201-M16*2-6H