With low density, high strength, good machinability, aluminum as the structural materials, can be made into various section bars, tubular products,high steel plate, etc. to fully tap materials’ potential for improving structural parts strength and rigidity. High-speed cutting has evolved into practical stage, structural parts are the main field of its application,particular for aluminum alloy structural parts and composite materials withwide application. Thus, the security, thermal-stability, dynamic balance are the critical factors that influence high-speed machining of tools.

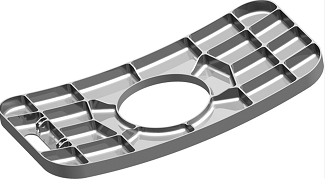

Face milling

High-speed milling series: aluminum cutter body with high strength and light weight. Unique tool clamping system design: flexible run-out adjustment system, high-pressure internal coolant; combined with high-precision inserts can achieve high quality, high precision, high efficiency, high stabilitymachining for various materials.

Profile milling

EPX series tools, ground peripheral and edges with high insert indexing repeatability and sharp edges with drop-out proof design to ensure high reliability. Adopting screw to adjust dynamic balance for reducing vibration and improve cutting speed greatly.

EPX series tools, ground peripheral and edges with high insert indexing repeatability and sharp edges with drop-out proof design to ensure high reliability. Adopting screw to adjust dynamic balance for reducing vibration and improve cutting speed greatly.

Cavity roughingAL-3W series endmills with wave edges,is suitable for aluminum alloy materials roughing.

AL-3R-AIR extra-high-speed milling series suitable for aluminum alloy materials high-speed finishing.

More productive, innovation-oriented, and highly effective products and industrial solutions, Please visit our ZCCCT products catalog.