Titanium alloy are getting more and wider application, it

is major material for structural parts of aircraft vehicle. We developed –NM

geometry inserts targeting the titanium alloy materials machining, such as

RCKT-NM, ADMT-NM, SPGT-NM specification are matching with a complete range

of specifications FMR, EMP/HMP milling tools and ZTD U drills, can achieve

high-efficiency machining for titanium alloy structural parts.

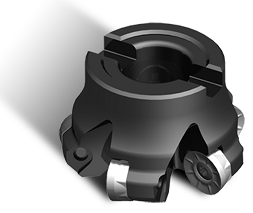

Face milling

FMR 02 series, standard tool mounted with RCKT-NM inserts for

normal machining. It can shorten machining time with wide application in

roughing and semi-finishing.

EMP series, HMP series tools mounted with ADMT*-NM series inserts; specially designed for titanium inserts for slot milling, side milling and cavity machining.

Drilling

SD series

twist drills

The main

cutting edges are convex curve, with longer edges to reduce load on each unit,

also lower wear rate; rake angle of flute “g” is a negative value, larger point

angle facilitate heat-dissipation.

ZTD U drills

Brand-new

treatment of conductor materials with high hardness and longer tool life; new

positioning insert mounting angle with excellent chip breaking performance and

low vibration in operation; mounted with SPGT*-NM insert, is suitable for titanium

and high temperature alloy machining.

Solid

carbide ball-nose end mills, sharp edges and large chip pocket, is suitable for

roughing and finishing; flat and smooth of end face, no sharp point, better

wear resistance; high-performance KMG 405 coating further improved wear

resistance.