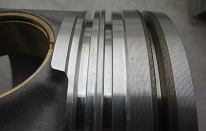

Piston is one of the most important parts of engine. It can bear air pressure drive crankshaft by transmitting from piston pin to connecting rod. When engine is at work, the piston bears high temperature, high pressure, heat load and mechanical load. Piston, as a vital component for transmitting energy of automotive engine, has special requirements on its materials: low density, light weight, good thermal conductivity, and low thermal expansion coefficient; sufficient high temperature strength, wear resistance and corrosion resistance, good dimension stability. Additionally, it also embraced the feature that easy to manufacture and low-cost.

Piston can be applied in cast iron, forged steel, cast steel and aluminum alloys and other materials. Among them, aluminum alloys has been widely used in piston manufacturing by its merits of lightweight, good thermal conductivity, lower coefficient of thermal expansion and other features.

External turning, end face and seam allowance machining

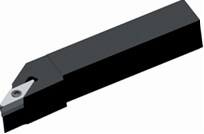

SVJCR2020K16

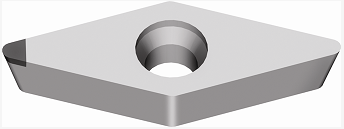

Insert VCGX 160408-LC/YD 101 for roughing,special geometry for aluminum machining, unique chip breaker and large rake angle made edges sharper, while guaranteeing effective chip breaking, also can achieve soft cutting action.

VCGW 160408/YCD 011, PCD cutting tool, with great wear-resistance and heat-conductivity, is mainly applied in non-ferrous and non-metallic machining with high-speed, high-efficiency and high-precision.

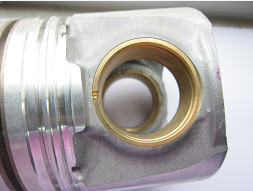

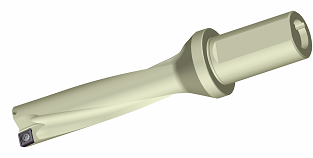

Pinhole machining

Drilling : ZTD series U- drill, good angle of installation, optimized internal structure, solid drill body, can realize high-stable machining at greater feed rate.

Rough boring: Adjusted and modular rough boring with double-edges, tooth-shaped contact surface ensure large enough contact area, can greatly improve the rigidity of tool, achieve double-edges synchronized adjustment, unsynchronized adjustment and unequal height boring,etc.

Finish boring: With internal coolant supply, improve chip evacuation performance as well as extension tool life. Each unit of scale indicates 0.005 mm, which means increase or decrease of 0.01 mm.

Machining for return chute in pin hole

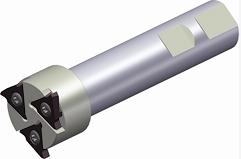

SMP 05 side and face milling cutter,combined with QC series shallow slots inserts, can realize slotting, plunge milling, back chipping and other operations. Special structure and process design enable higher mounting precision and machining precision, the same one insert is suitable for assembling in internal, external turning tool holders and groove milling tool holder.

Top slot machining

Special tools, mounted with ZILD 08-LC insert, tailored profiling process technique and high efficiency.

S20R-SVQCR tool holder mounted with VCGX-LC insert, suitable for aluminum alloy profiling with high precision.

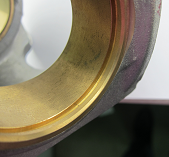

Ring groove machining

QEFD tool holder combined with ZTFD-EG inserts, edge width can be defined according to work piece groove width, high manufacturing precision, able to precision grooving and turning.