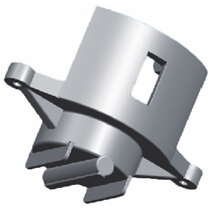

Cast iron and cast aluminum are typical materials of calipers, light weight calipers not only can lower oil consumption and improve braking efficiency, also can improve automotive handling performance, but with low production efficiency and higher costs. Thus, cast iron calipers are still the mainstream products in calipers section.

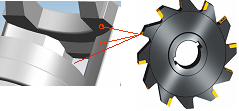

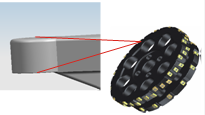

Jack catch surface, bore hole top surface---SMP03 series face and side milling cutter

One pass can finish three faces

Open chip pocket makes chip evacuation more smooth, can realize high metal removal rate.

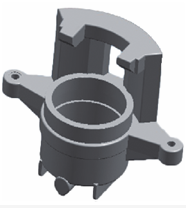

Inner hole boring---non-standard boring tool

This tool is non-standard boring tool,designed with small tool holder structure, if tool holder is broken, just change it directly. Necking design can prevent collision.

Upper and lower sides of mounting hole on calipers——SMP04 non-standard face and side milling cutter

SMP04 non-standard face and side milling cutter, can milling top and bottom surface at the same time, only one operation is needed to finish the machining process. The diameter of milling cutter and slots width can be defined according to customer caliper size.

Mounting hole drilling---SU series drills

140 degree point angle, reduce the feed force in the initial stage. Good self-centering performance, improve hole-machining precision.

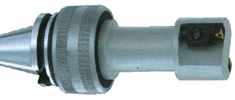

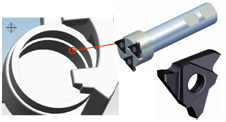

Milling for Internal shallow groove of cylinder hole---SMP 05 groove milling cutter

SMP05 series tool is special developed for internal groove milling. OC series inserts, with good economical efficiency and high precision. Groove width can be defined as per customer requirement, round head and square head for selection.

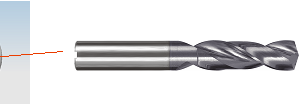

Milling caliper dorsal pore groove--- PM series solid carbide tool

PM series endmill is suitable for worse working condition machining or extra-hard material machining; Sharp edge-protected PM endmill possesses excellent edge rigidity and less like to breakage.