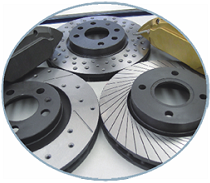

The material of brake disc is based on national standard of cast iron-250 standard, HT250 for short, is equal toG3000 United States standard

ventilated brake disc

normal brake disc

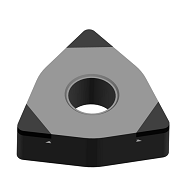

External and end face machining——external tool holder with 95 degree

D type tool holder, double clamping system,more firm and reliable inserts clamping

Mounted with W type insert, 6 edges bring more economic benefits

95 degree entering angle, both for turning of external and end face

YBD152/WNGA080408 insert for roughing

YCB012/WNGA080404-3 insert for finishing

Milling of grooves on end face—— PM series ball-nose endmills

grooves milling

High rigidity tool structure reduces tool vibration;Peripheral edge and ball edge can realize seamless connection, proper center design of ball edge greatly improves surface quality; ultra-fine grain cemented carbide substrate with excellent wear-resistance, nano-level coating ensures excellent wear-resistance and thermal-stability.

bolt-hole making——SU series stepped drill

Only one operation can finish hole-making and chamfering

Drilling for heat dissipation hole—— solid carbide drills

heat dissipation hole

PC series drill with straight flute,excellent conductivity, good rigidity, higher hole quality.