Machining procedures of disc ring parts are simple, usually roughing before finishing. But due to the complex shape of work piece, it is essential to take collisions into consideration in the machining process. Non-standard tools are frequently applied in disc ring parts machining.

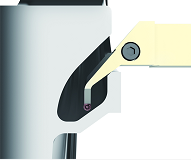

Dovetail slot milling

Perfect combination of special tool holder and inserts

for dovetail slot milling

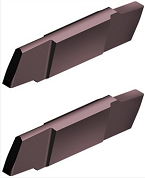

Fully ground, double-end slot milling inserts with high economy, high indexing repeatability

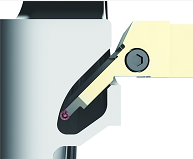

R end 90°slot machining tools

Fine ground, for slot turning with small space

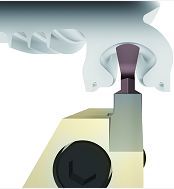

R end angle head slot cutter

Convex locating, fine ground lower locating surface, excellent

indexing repeatability

Special tool holder combined with standard slot

inserts, for deep grooving operations.